Using real-time data on heat stress risk in dairy cows

Monitoring heat stress risk on dairy farms in real-time has become possible with the development of sensor technologies measuring temperatures and humidity in cow sheds. This is increasingly becoming common practice to alert dairy farmers of when their cows are at risk of experiencing heat stress and then take swift action in favour of cow well-being.

Applying real-time data on heat stress risk in dairy field trials – a case study

by Gwendolyn Jones, Product Manager Gut Agility Activators, published in International Dairy Topics, September 2022

It also presents opportunities to evaluate nutritional strategies more effectively in terms of their capacity to mitigate the negative impact of summer heat on cows in a commercial farm situation. This article describes a case study where those new technologies were applied in a dairy field trial to assess the effect of a nutritional technology on milk production and quality during the summer period.

Monitoring heat stress risk on farm

Even low levels of heat stress can negatively impact milk production and reproductive performance in dairy cows and at higher levels it increases the incident rate for mastitis. The question for a long time was how to determine the heat stress risk cows are exposed to on farms early. It is now well known that it is not only a question of temperature but also humidity, which determines the negative impact on dairy cows. As a result, calculating the Temperature Humidity Index (THI), which combines air temperature with relative humidity, has been established as an indicator for heat stress risk.

New sensor technologies that have only become available in the past couple of years allow farmers to measure temperature and humidity inside sheds, which is then relayed by Wi-Fi as live THI readings to their smartphones or computers. This is helping dairy farmers to correlate milk production and fertility blips with THI data at any given point in time.

Collective data from research has shown that cow milk production can be affected when daily average THI exceeds 68, whereby mild heat stress has also already been reported at a THI score of 62 in dairy cows on some farms. This depends on the level of milk production in the dairy herd, since high- producing dairy cows are more susceptible to the effects of temperature and humidity in their environment.

Wireless transmission of real-time data is essential in providing producers with the relevant information that facilitates informed management decisions in relation to reducing the effects of heat stress as the event is occurring.

Aside from alerting farmers of potential cow discomfort, climate sensors and other precision dairy technologies offer a wide range of data points that can be taken advantage of when running field trials on dairy farms to assess nutritional strategies and feed additives.

Dairy farm case study

The effect of THI on milk production parameters was looked at on a dairy farm in Austria with 50 milking cows during the summer period. The breed on this farm was Fleckvieh, with an average milk yield of 34.5kg/day. The cows were fed a TMR based on a mix of grass and maize silage and were supplemented with concentrate feed via the milking robot (DeLaval VMS). THI, and milk production data were collected, after a short adaptation period in June, from July through to mid-October 2020.

Temperature and humidity were measured in real-time with a climate sensor from Smaxtec animal care GmbH in the cow shed and transmitted wirelessly to a base station to calculate the THI. Milk control samples were taken on a monthly basis to collect data on the following parameters: milk production (kg/d), milk fat (%), milk protein (%) and somatic cell counts (cfu/ml).

Results

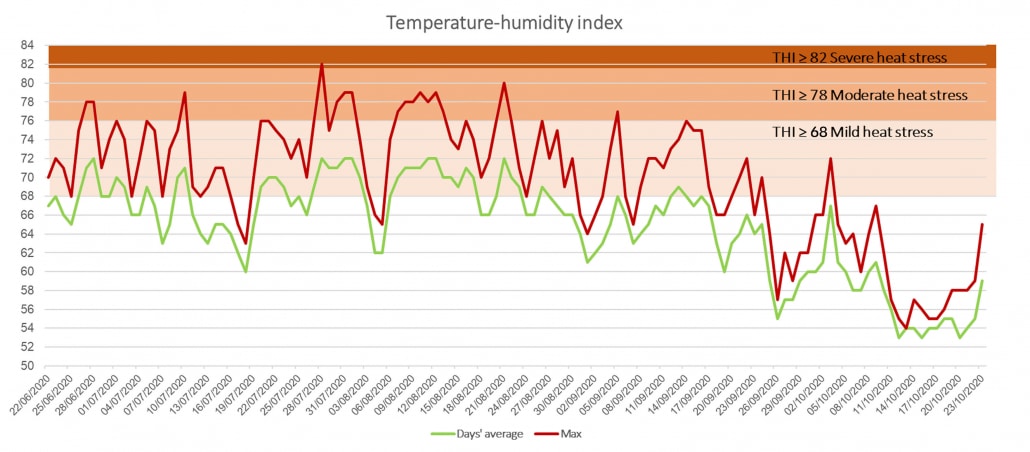

During the course of the study the mean daily THI (24 hours) ranged from 53-72 (Fig. 1). During the last week of July, the max THI reached up to 82. Maximum daily THI ranged from 64-82 from July to September, which occurred mainly from midday until the evening.

This means that cows experienced at least some mild level of heat stress most days from July to September and were exposed to moderate to high levels from mid-July to mid-August at some point during the day.

Fibure 1 THI measured via climate sensor in the cow shed over the trial period (July-October)

Results for milk production show that daily milk yield was on average +1.7kg/d higher for cows fed the product Anco FIT in the period from July to October (Fig. 2) but was particularly higher (+3.4kg/d) numerically in July where the maximum THI was recorded to be the highest.

Milk constituent levels were also maintained numerically at a higher level throughout the period of investigation, resulting in 8% higher milk protein yields and 10% higher milk fat yields and an economic advantage of 0.85/cow/day compared to the control group.

The number of cows with somatic cell counts indicating healthy udders (<100 x 1,000 cfu/ml) was on average 78% out of all cows from the group fed Anco FIT compared to 60% in the control group throughout the period of investigation (Fig. 3).

Conclusion

In conclusion, climate sensors installed in cow sheds can help to facilitate the evaluation of feed additives in cows at risk of experiencing heat stress in the field.

More accurate interpretations and potential deeper insights into cow adaptation to challenges are expected from real-time THI data that is correlated with fluctuations in daily automatic milk yield recording.

Related articles

Precision feeding in cattle to reduce environmental foot print